Most fluid power circuits use compressed air or hydraulic fluid as their operating medium. Whilst these systems are the same in many aspects, they can also have very different characteristics.

For instance, remote outdoor environments may use dry nitrogen in place of compressed air to eliminate freezing problems. Whereas hydraulic systems use a variety of fluids, from water to high temperature, fire resistant fluids; note that the fluid is different but the operating characteristics remain the same.

Most pneumatic systems run at low power, usually around 2/3 horsepower. This is due to air systems operating at relatively low pressure which can bring many advantages:

Due to the nature of compressing air, the initial cost of an air circuit is less than a hydraulic circuit, however the operating costs can be 5/10 times higher. It is the air motors which are the most costly components to operate, although they do not need to be cycled often, only when required.

As the power source, the air compressor itself is installed remotely and enclosed in the machine; pneumatic systems are generally quieter that the hydraulic counterparts as the noise is contained within the machine.

Air driven devices can be used for stability if a combination of air and oil is the driving medium, however they cannot hold objects rigidly in place unlike hydraulic actuators.

The benefits of pneumatic systems are:

With a hydraulic system, the same fluid is circulated repeatedly from a fixed reservoir.

As the fluid is a non-compressible liquid, the actuators it drives are easily controllable and accurate positions, speeds or forces can be obtained. The fluid used for most hydraulic systems are mainly mineral oil types, but other fluids such as ethylene, glycol or synthetic types are not uncommon.

Hydraulic systems have one central power unit which has hoses running to and from the outlets of the unit allowing hydraulic systems to operate several tools from the hoses. Another advantage of using a hydraulic system as oppose to a pneumatic system is that they operate at higher pressures, generating a higher force from smaller actuators which are less space consuming in a work environment.

To meet demand, main central power units are manufactured frequently, this is largely due to their many advantages:

There are however three main issues which operators of hydraulic systems will frequently encounter:

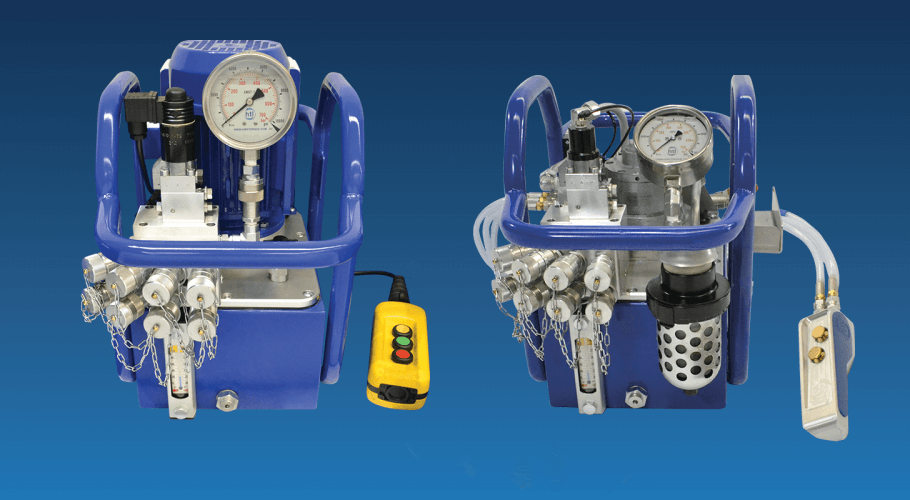

Here at HTL we understand that individual pneumatic and hydraulic system preferences are highly important, therefore we have developed a range of electric and air torque pumps to suit every requirement.

For more information or for an instant quote contact us today: call +44(0)1670 700 000 or email info@htlgroup.com.

Related articles: http://www.hiretorque.co.uk/the-difference-between-pneumatic-hydraulic-and-electrical-actuators/