There is not a single method of power transmission that is the best choice for all applications and some applications can even incorporate a combination of systems.

Fluid power is a term used to describe hydraulic and pneumatic systems as both of these technologies use a fluid to transmit power by simply moving it from one location to another, in this case the movement of liquid or gas. Mainly, the fluid used is oil, as a liquid, and compressed air, as a gas.

Power transmission, relating to electrical methods of power, relays the power used to control a motor which in turn allows for the speed and torque to be regulated.

Comparison of electrical, hydraulic and pneumatic systems can be compared to aspects such as an energy source, energy storage, energy cost, distribution system, linear actuators, rotary actuators and controllable force. (¹)

Throughout this article we are firstly going to consider the features of the systems themselves and go back to basic with how the internal linear actuators work.

An actuator is simply a component of a machine that moves or controls loads and mechanisms. The actuator is operated by energy, either pressurised fluid, air or electricity, typically sourced by utilising a pneumatic, hydraulic or electric pump. The energy is then converted into a motion or force to achieve movement or control. (²)

To understand the differences between pneumatic, hydraulic and electric actuators we need to delve into the mechanics of how each system derives its force.

Pneumatic linear actuators consist of a piston inside a hollow cylinder. Pressure from an external pneumatic pump moves the piston inside the cylinder and as pressure increases the cylinder moves along the axis of the piston, creating a linear force. The piston returns to its original position by either a spring back force or fluid being supplied to the other side of the piston.

The benefits of pneumatic actuators come from their simplicity.

Pneumatic actuators’ typical applications involve areas where the conditions involve extreme temperatures, a typical temperature range is -40°F to 250°F.

In terms of safety and inspection, using air and pneumatic actuators avoids using hazardous materials. They also meet explosion protection and machine safety requirements because they create no magnetic interference due to the lack of motors.

All of these advantages create a cost effective method of power.

Pressure losses and compressibility of air makes pneumatic actuators less efficient than other methods. Compressor and air delivery limitations results in operations at lower pressures to have lower forces and slower speeds.

To be efficient, pneumatic actuators must be sized for a specific job. Hence, they cannot be used for other applications.

Even though air is readily available, it can be contaminated by oil or lubrication, leading to downtime and maintenance which incurs costs.

Companies still have to pay for compressed air supply as well, making it a consumable, along with the compressor and line maintenance costs.

Hydraulic linear actuators operate similarly to pneumatic actuators, but an incompressible liquid is present from a pump, rather than pressurized, air is what moves the cylinder.

Hydraulic actuators are robust and suited for high force applications. They can produce forces 25 times greater than pneumatic cylinders of equal size, operating in pressures of up to 4,000 psi.

A hydraulic actuator can hold force and torque constant without the pump supplying more fluid or pressure due to the incompressibility of fluids.

Hydraulic actuators can have their pumps and motors located a considerable distance away with minimal loss of power.

Hydraulic fluid will leak and similarly to pneumatic actuators, loss of fluid leads to less efficiency and cleanliness problems, resulting in potential damage to surrounding components and areas.

Hydraulic actuators require many complementary parts, including a fluid reservoir, motor, pump, release valves, and heat exchangers, along with noise reduction equipment.

An electric linear actuator converts electrical energy into speed and torque. A mechanically connected electric motor turns a lead screw. When the screw rotates, the nut gets driven along the threads, the direction the nut moves in depends on which direction the screw rotates.

Electrical actuators offer the highest precision control setting. Their setups are scalable for any purpose or force requirement and are quieter than pneumatic and hydraulic actuators, allowing for smooth and repeatable usage.

There is zero risk of fluids leaking, eliminating any environmental hazards.

Electrical actuators are not suited for all environments, unlike pneumatic actuators, which are safe in hazardous and flammable areas.

A continuous running motor will overheat, increasing wear and tear on the reduction gear.

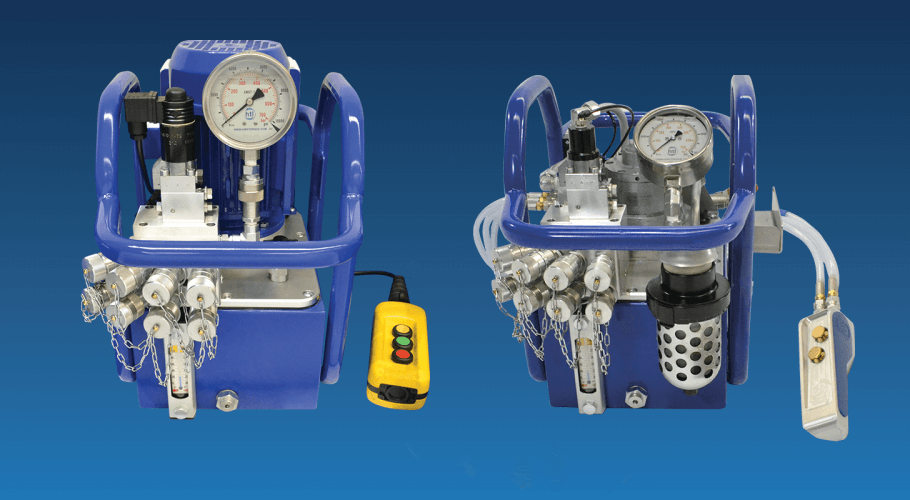

Now we understand what functions ultimately make the difference between the three types of pumps and what each of their beneficial features are, you can suit your requirement to HTL Groups range of pumps.

For instance, when working in a hazardous environment Pneumatic and Hydraulic systems should be considered over Electrical. However, for an accurate level of torque, Electrical systems are quicker and more user friendly.

With a wide range of pumps available:

HTL Group can supply equipment to suit your hire and sale requirements.

For further information or to get an instant quote of HTL Group’s range of pneumatic, hydraulic and electric pumps call +44(0)1670 700 000 or email info@htlgroup.com.

(¹) https://me-mechanicalengineering.com/comparison-electrical-hydraulic-pneumatic-systems/