Bolting applications are used across the industry to assemble products ranging from pipelines to heavy-duty earth movers to cranes, bridges and many more. Their principal function is to create a clamping force across the joint, which can sustain the operating conditions without loosening.

Correctly tightened bolts make use of their elastic properties and to work well they must behave like springs. When load is applied, the bolt stretches and attempts to return to its original length, creating a compressive force across the joint members.

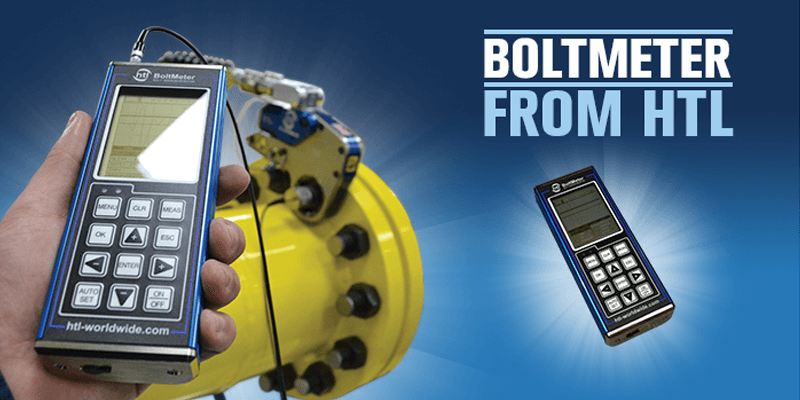

HTL’s BoltMeter uses ultrasonic wavelengths to measure the elongation, stress and load in bolts. With a user-friendly interface and simple to use features, it quickly and accurately measures the required bolting information and produces a reading on the display screen. With a built-in data recording system and a data port, information can easily be extracted to excel and manipulated to suit.

BoltMeter maintains its accuracy as it measures the time the wave takes to pass through the bolt. There is no requirement for calibration or servicing of BoltMeter as it relies on the ultrasonic sound wave, produced by the magnetic point placed on top of the bolt, which is then reflected back when the wave encounters a change in density.

The ultrasonic wave gives an accurate measurement of the bolt’s length which is the initial bolt reading. The bolt is then torqued or tensioned, and BoltMeter is connected again. The difference between the initial reading and the final reading is the bolt’s elongation. The same method applies if the reading required is for stress and or load measurements.

HTL’s BoltMeter is crucial to the bolting process as monitoring bolt preload over the lifetime of a bolt highlights bolt relaxation and the loosening of bolts over time.

BoltMeter can highlight implications and inconsistencies, such as if the load in the bolt is too high, low or not uniform:

In principle, there are two methods of tightening nut and bolt assemblies:

1.Uncontrolled

This method uses equipment and processes that cannot be measured and preload is applied to a bolt and nut using a spanner, hammer and other impact tools. While creating a bolted connection, the load is unknown, causing uneven bolts stresses/elongation/load, leading to bolting failures.

2.Controlled

Controlled bolting methods utilise calibrated and measurable equipment, where processes such as bolt tightening procedures, are adhered to. This method refers to the two main techniques of bolt tightening both achieve the preload in a bolt and nut assembly:

The above methods can be coupled with BoltMeter to increase preload accuracy and enables the user to monitor bolts during maintenance checks.

HTL’s BoltMeter offers a solution to accurate bolting parameters, ensuring that bolts retain the exact load required to maintain a secure clamping force, reducing bolting failures.

To enquire about HTL’s BoltMeter email info@htlgroup.com or call +44 (0)1670 700 000.

Related Articles:

https://www.hiretorque.co.uk/failure-modes-of-bolts-and-bolted-joints/

https://www.hiretorque.co.uk/preventing-bolted-flange-joint-failure/

https://www.hiretorque.co.uk/why-use-bolting-software/

https://www.hiretorque.co.uk/preloading-and-tightening-with-the-right-tool/