Across a vast range of industries, there is a need for tools that provide easy flange maintenance and the assurance that joints will be leak-free. Bolt Tensioners are regularly the tool of choice for engineers performing flange maintenance as they can provide the joint integrity assurance that their operations require.

Bolt Tension is the stretch or elongation of a bolt that provides the clamping force of a joint. The bolt is preloaded and stretched during the process. When this has been completed correctly, with the nut tightened and the tensioner load removed, the bolt will automatically want to return to its original length. It is this spring-like action that creates tension and results in a clamping force across the bolted application.

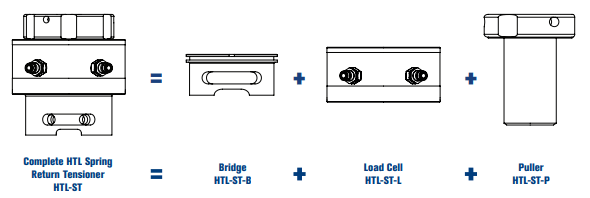

A bolt tensioner is made up of 3 essential components, the Bridge, Load Cell, and Puller.

On HTL Spring Return Tensioners the load cell features dual-port connection points. This allows operators to ‘daisy chain’ tensioners together with hoses, providing a more efficient operation.

Tensioners also feature a socket on the bridge, which turns the hex nut during operations.

To simplify the process, we have highlighted the 5 key steps in the bolt tensioning process.

To determine which bolt tensioner to utilise for your specific application, there are a number of variables to consider first.

Luckily, HTL can accommodate for all types of applications. The HTL Spring Return Bolt Tensioner range covers bolt ranges from ¾”- 4”.

There are 2 main types of bolt tensioners available: Spring Return, and Manual Return. So… what is the difference?

Spring Return Tensioners allow greater efficiency and warrant ease of use for the operator due to the improved design including the anti-slip tool surface to enhance grip. The design also incorporates dual ports which allow the operator to daisy chain multiple tensioners together, removing the need and expense of ‘T’ pieces. Spring Return Tensioners ultimately increase and improve the productivity and safety of the operator by eliminating the need to manually wind down the threaded puller.

Manual Return Tensioners can be considered a slightly less-safe alternative as they require the operator to manually wind down the threaded puller. This means that the operator needs to get close to the tool, with hands often near pinch points.

HTL Group can supply a variety of tensioning options for your operations. To emphasise our dedication to operator safety, HTL Group stocks the safe, reliable Spring Return type – ideal for topside applications. Subsea Tensioners are also available, and these include a host of safety features to ensure divers can execute operations with peace of mind, knowing their equipment will perform, even in the harshest environments.

Click here to see our full range of tensioning equipment, including pumps and hoses.