From the end of 2004, worldwide renewable energy capacity grew at rates of 10–60% annually for many technologies. For wind power and many other renewable technologies, growth accelerated in 2009 relative to the previous four years. More wind power capacity was added during 2009 than any other renewable technology. However, grid-connected PV increased the fastest […]

The Failure of Bolts and Bolted Joints, in particular, can be a significant source of concern for engineers. Frequently, assumptions are made to assess whether the joint is capable of sustaining the forces applied to it. Failure of a single bolted joint can have disastrous consequences for the reliability and safety of bolted connections. The […]

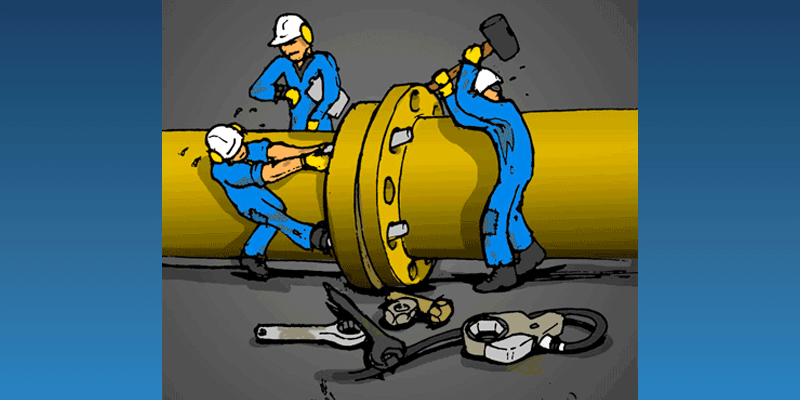

Bolted flange joints have the potential to leak, but steps can be taken to prevent this at plants and installation sites. Consequences Flange joint failure regularly occurs within the Oil and Gas industry, causing millions of pounds worth of damage, therefore preventing leakages and joint failure is a main priority. In addition to carrying out […]

Research shows that a spare part strategy can improve fault-related downtime, therefore choosing a reliable supply partner with stock readily available on the shelves is crucial. Whether it be for turbines, construction, oil refineries, quarries, offshore parts can fail, resulting in downtime and incalculable costs. With HTL’s extensive stock capacity and 24/7 service with deliveries […]

Contamination in hydraulic systems is now recognised as the most frequent cause of malfunction or failure of hydraulic equipment. Depending on the nature, size and/or amount of contaminant, the effects can be: Reduced component service life Machine malfunction, mainly when operating near-maximum capacity Risk of frequent breakdowns under the same conditions Production rates below scheduled […]

The process of troubleshooting should always begin with checking and eliminating the easy things first. When problems occur with hydraulic equipment, before the expense of hiring a technician is incurred, carry out an informed assessment of the problem and eliminate the obvious. General Systems In general, troubleshooting maintenance procedures are for general systems. It is […]

It would be a virtually impossible task to try to document the cause and remedy of every possible fault that could occur on even the simplest hydraulic system. For this reason it is necessary to adopt a logical approach to troubleshooting, in order to locate a fault as quickly and accurately as possible. Downtime on […]

Most fluid power circuits use compressed air or hydraulic fluid as their operating medium. Whilst these systems are the same in many aspects, they can also have very different characteristics. For instance, remote outdoor environments may use dry nitrogen in place of compressed air to eliminate freezing problems. Whereas hydraulic systems use a variety of […]

The consequences of proper preload not being developed or maintained can lead to joint failure. Therefore, it is crucial to fully understand the required preload level for every joint before achieving it through a suitable tightening method, the correct tightening sequence and by using the correct torque wrench. Calibration and Certification Specifications by BS EN […]

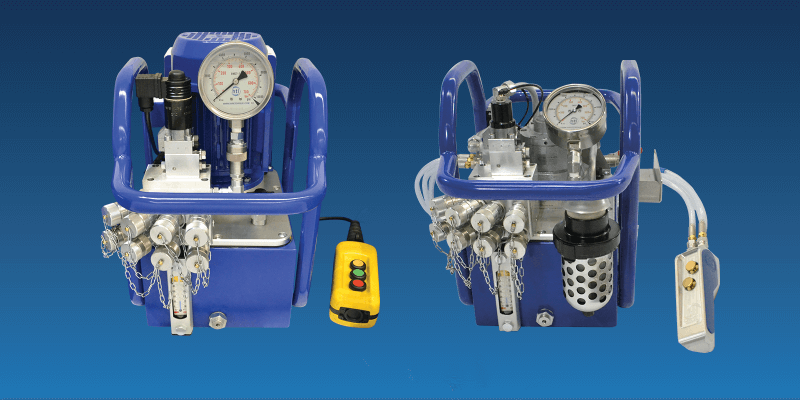

HTL’s range of innovative flange maintenance equipment provides fast, safe, cost effective and simple solutions to flange alignment, flange spreading and flange pulling. Traditional vs. HTL Flange Spreading Manual tools are imprecise and pose high risk of damage to flanges and injury to personnel, they are: High risk Hazardous Inefficient Complex Labour intensive Damage to […]